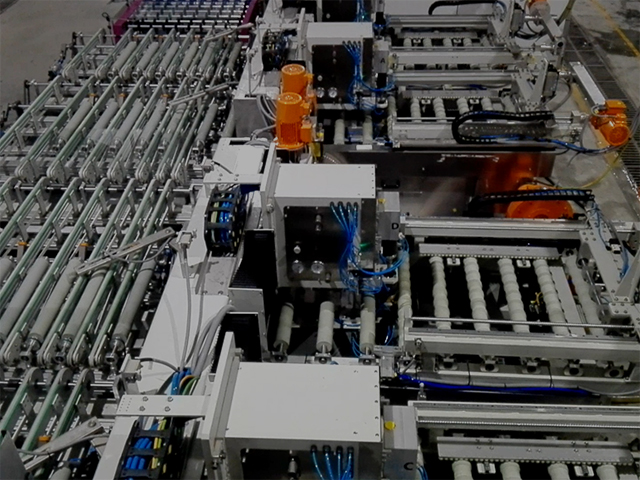

Drilling Machines

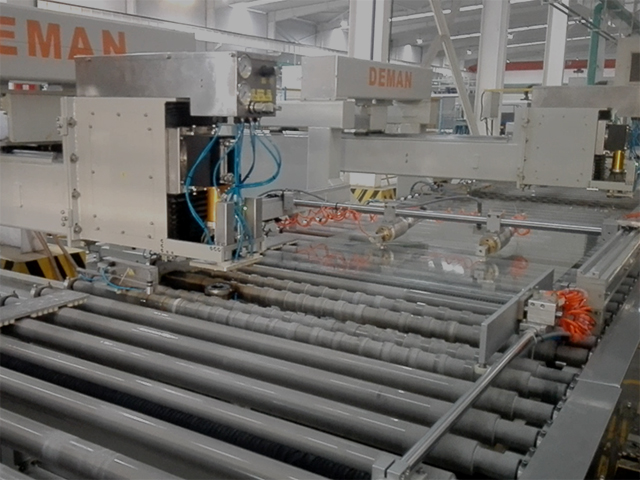

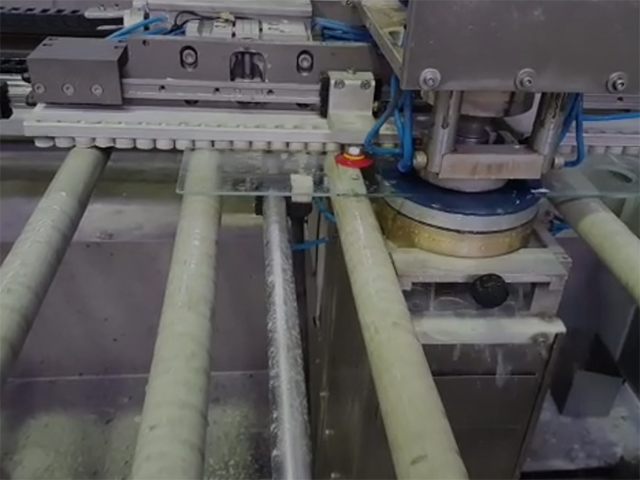

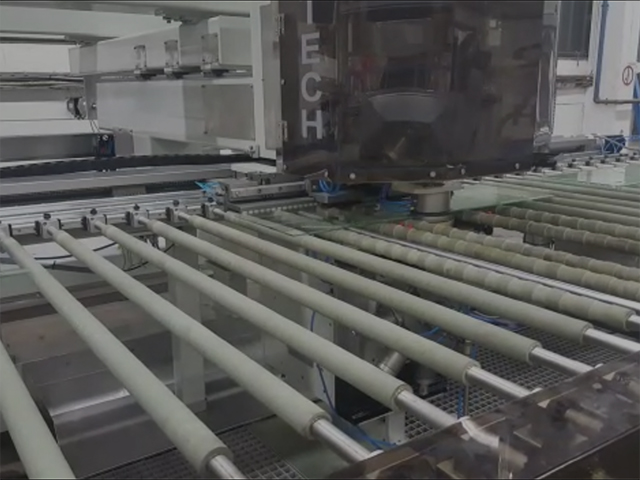

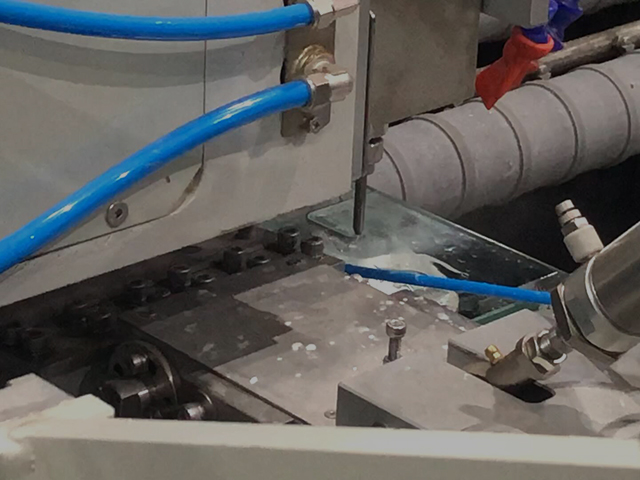

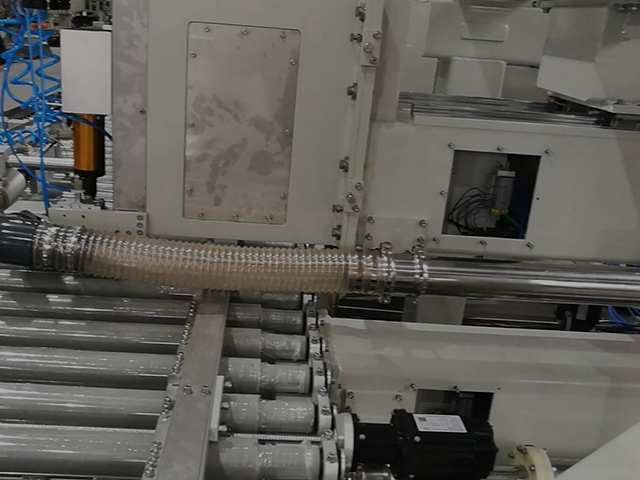

DEMAN Drilling Machines for Flat Glass

are manufactured according to German technology and have a modern design.

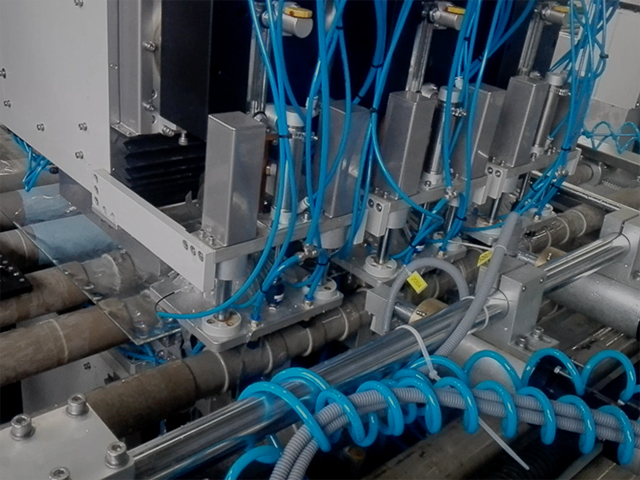

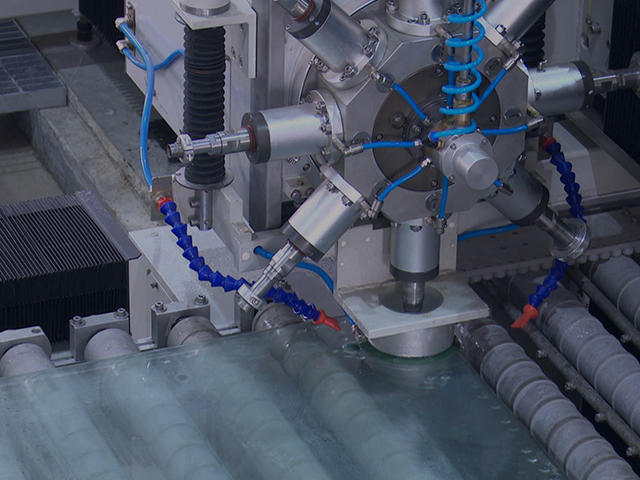

We build different types of Flat Glass Drilling Machines:

Single-Head Drilling Machines, Double-Head Drilling Machines,

3-Head Drilling Machines, 8-Head Drilling Machines,

Water Jet Cutting Systems and CNC Portal Drilling Machines.

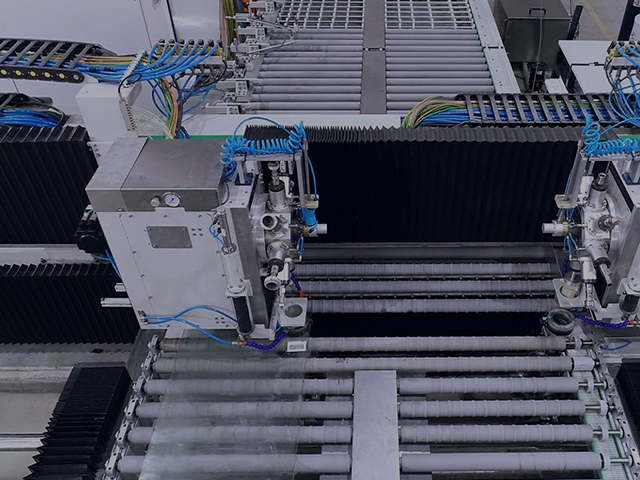

We offer Glass Processing Machines for any application:

Flat Glass Drilling Machines, Furniture Glass Drilling Machines,

Architectural Glass Drilling Machines, Insulated Glass Drilling Machines,

Solar Glass Drilling Machines and Special Machines

SEND US YOUR NONBINDING INQUIRY

Do you have any questions, or would you like to place an order?

We will keep your data that you send with this inquiry confidential and not pass it on to third parties at any time. Please read our privacy policy regarding this.

Make a call.

Or send us an email.

Make a call

Or send an email.